Dr. Dragana Đorđević Čegar

Dragana Đorđević Čegar is the Global Software Quality Lead at Schneider Electric with over 12 years of expertise in software quality. She is the author and/or co-author of several patents and more than 30 publications; Licensed intact Provisional Assessor ASPICE and Instructor at the University of California San Diego.

She has been the Global Manager Quality Customer Programs and QMS at TTTech Auto AG and has 10 years of experience in the automotive software industry.

She received the BSc and MSc degrees in electrical and computer engineering with focus on communication and information technology, from the Electronic Faculty, University of Niš, Serbia in 2011 and 2012 respectively. Dr. Đorđević Čegar also received PhD degree in electrical and computer engineering with focus on artificial intelligence from the Faculty of Technical Sciences, University of Novi Sad, Serbia in 2021. While working on PhD she was part of Quaint community tightly collaborating with several Universities such as Polytechnic University of Nantes, EPFL, NTNU, Vrije Universiteit Brussel etc.

The primary industry focus of Dr. Đorđević Čegar is how to deliver software quality in automotive embedded safety systems, establishment of automated software quality metrics and implementation of AI in automotive software industry. As Provisional Assessor and responsible for Quality Customer Programs and QMS she was actively preparing, driving and participating in ASPICE, ISO 26262, Cybersecurity and ISO 9001,14001, 27001 etc. audits and assessments. Thru her career as Automotive Software Quality Manager she participated and ensured quality of delivery to VW group OEMs, AutoEver (Hyundai), SAIC motors, BMW etc.

She is author or/and co-author of several patents and more than 30 publications. During her career she was working as patent portfolio engineer and therefor actively involved in creation of RT-RK Institute patent portfolio.

References

Đorđević Čegar, D et al. Modelling effects of S3D visual discomfort in human emotional state using data mining techniques. Multimed Tools Appl 79, 19803–19829 (2020). https://doi.org/10.1007/s11042-020-08844-3

Patent Number 58028: “Method for patent classification based on international patent classification codes and technology groups”; Priority date P-2013/0289, 08.07.2013.

Patent application A1: “Method for determining the emotional state of the user due to the visual impact”; Priority date P-2016-1174, 23.12.2016.

Image Quality Assessment Using Takagi-Sugeno-Kang Fuzzy Model IV038; 2014 3rd International

Conference on Image, Vision and Computing (ICIVC 2014), Paris, France, Vol., Nr., Str.0-0, ISBN:, ISSN:, Publisher: ICGIP proceedings (and included in SPIE Digital Library)

Toward Certification of 3D Video Quality of Experience through Inter- Laboratory Comparison; 4th

International Workshop on Perceptual Quality of Systems (PQS 2013), Vienna, Austria, Vol., Nr., Str.67-72, ISBN:, ISSN:, Publisher: FTW Forschungszentrum Telekommunikation Wien GmbH

Courses

Learn specifics about projects and processes in automotive engineering and how they impact safety.

This course brings the essential understanding of automotive quality as a prerequisite for functional safety management. The key concept of the training is to bring an understanding of why quality, process, and project management are basics for producing safety-critical systems. By the end of the course, you will learn how to grow a quality culture and ensure organizational strength by using a specific quality measurement framework. Furthermore, the course will bring the importance of processes and procedures, the connection between safety and quality management, and the project management process through automotive recommendations and standards. At the end of the course, focus will be given to assessment procedures in order to ensure a deep understanding of how assessments are held in the automotive industry as requested by the majority of OEMs.

Course Topics:

- Quality management, organizational strength triangle, quality dimensions and disciplines, main principles of Quality Management System (ISO 9001), key characteristics, PDCA (Plan-Do-Check-Act) cycle;

- Key Performance Indicators (KPIs) and Key Activity Indicators (KAIs);

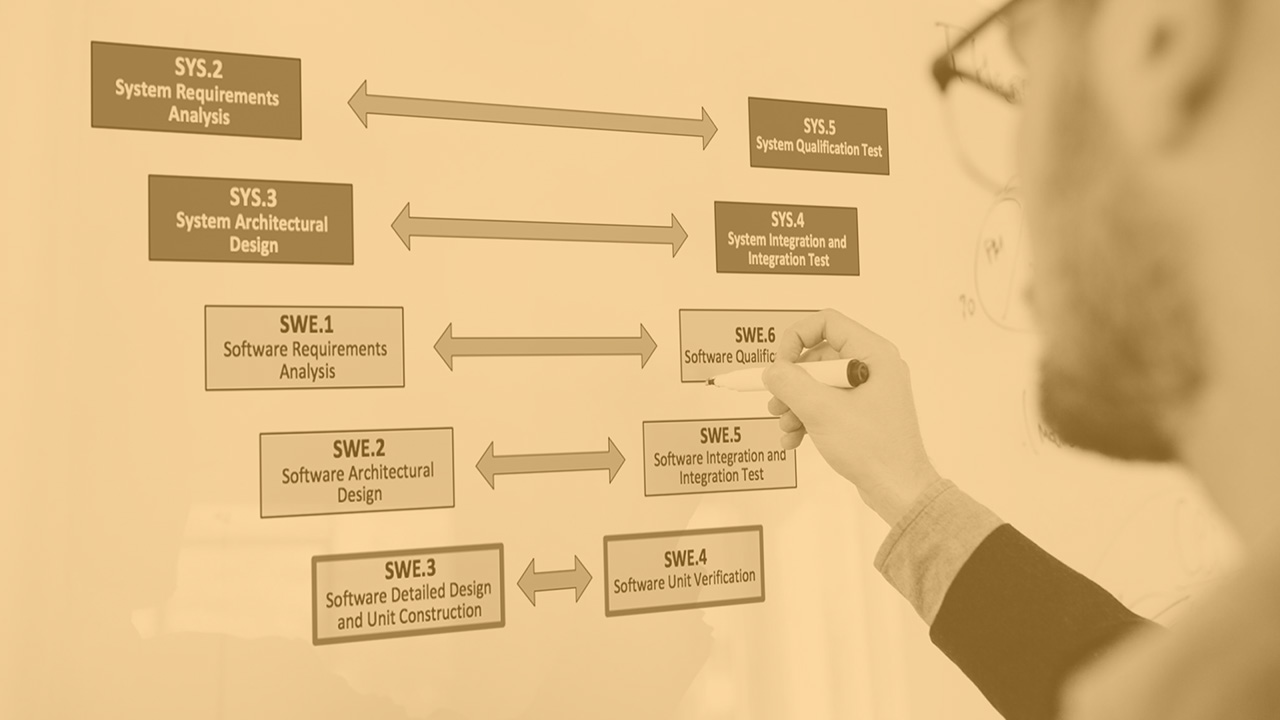

- Automotive SPICE: The basic concept of measurement frameworks with specific insights on ASPICE (ISO 15504);

- Project management: The management process through the ASPICE framework including best practices and work products mandatory to fulfill ASPICE Level 1 and BPs;

- Quality Assurance, Configuration Management, Problem Resolution, Change Request Management;

- Engineering processes Development: Traceability and basic practices of system and software requirements, as well as system design and software architecture together with unit construction processes;

- Engineering processes Testing: Traceability and basic practices of system, software, and unit testing on all levels.

Modules:

Requirements

Software: Chrome browser.

Hardware: Computer with an Internet connection, working speakers, and microphone.

Prior knowledge: Students should have a basic understanding of projects from their previous engineering or technical experience or previous studies. Students shall have basic knowledge of system and safety engineering.