This course brings the essential understanding of automotive quality as a prerequisite for functional safety management. The key concept of the training is to bring an understanding of why quality, process, and project management are basics for producing safety-critical systems. By the end of the course, you will learn how to grow a quality culture and ensure organizational strength by using a specific quality measurement framework. Furthermore, the course will bring the importance of processes and procedures, the connection between safety and quality management, and the project management process through automotive recommendations and standards. At the end of the course, focus will be given to assessment procedures in order to ensure a deep understanding of how assessments are held in the automotive industry as requested by the majority of OEMs.

M1: Quality Management Explained

https://academy.nit-institute.com/wp-content/uploads/2024/10/AQPM-M01.png

The lecture includes an explanation of what is quality management, why we need quality management, organizational strength triangle, quality dimensions and disciplines, main principles of Quality Management System (ISO 9001), key characteristics, and how PDCA (Plan-Do-Check-Act) cycle works. The lecture includes the exercise of defining corrective actions in the PDCA register as a key concept of continuous improvement project management.

Participants will summarize the main steps to establish a mature Quality Management System, discuss continuous improvement using the PDCA register template, create corrective actions and methods for checking effectiveness, and explain the overall cycle, including effectiveness checks and lessons learned.

2 hours 30 minutes

M2: Quality Management and Processes

https://academy.nit-institute.com/wp-content/uploads/2024/10/AQPM-M02.png

Understanding how quality is connected with processes and safety management. The lecture explains the differentiation between processes and procedures. The key aspect of the lecture is to understand Key Performance Indicators (KPIs) and Key Activity Indicators (KAIs) as an important tool for measuring the processes while acting as quality, safety, or project manager. Defining effective KPIs is part of the exercise.

Participants will discuss the differences between metrics, measures, and KPIs with examples for each. Select a process to define SMART KPIs, and explain how one KPI meets the SMART criteria.

2 hours 30 minutes

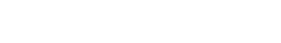

M3: Introduction of Automotive SPICE

https://academy.nit-institute.com/wp-content/uploads/2024/10/AQPM-M03.png

The lecture is opening the introduction of Unit 2 and summarize the basic concept of measurement frameworks with specific insights on how it is done thru ASPICE (ISO 15504) recommendation as the widely used framework. Thru this lecture students will learn how to use ASPICE guidelines and interconnect processes in the V model.

Participants will address the impacts of receiving a change request and list all work products that need to be updated

2 hours 30 minutes

M4: MAN.3 Project management

https://academy.nit-institute.com/wp-content/uploads/2024/10/AQPM-M04.png

The main aspect of this lecture is to introduce the management process thru the ASPICE framework including best practices and work products mandatory to fulfill ASPICE Level 1 and BPs. It will include Generic practices on Levels 2 and 3.

Participants will explain the sequence of steps to establish MAN.3 in a software project, including the initial project step, resource planning and competence assurance, and project monitoring techniques, and create a “table of contents” for a Project Management Strategy based on MAN.3 objectives.

2 hours 30 minutes

M5: Supporting processes

https://academy.nit-institute.com/wp-content/uploads/2024/10/AQPM-M05.png

Going thru Quality Assurance, Configuration Management, Problem Resolution, Change Request Management the students will learn basic practices, outcomes, and generic practices of the supporting processes.

Participants will explain the steps to resolve a defect in the Software Architecture Design process, including impacted processes, changes to Configuration Management, and measures to ensure the defect does not recur and quality is maintained.

2 hours 30 minutes

M6: Engineering processes Development

https://academy.nit-institute.com/wp-content/uploads/2024/10/AQPM-M06.png

Will demonstrate traceability and basic practices of system and software requirements, as well as system design and software architecture together with unit construction processes. After this lecture students will be capable to connect all processes on the left side of the V model.

Participants will outline the steps to resolve an issue where a Safety System Requirement cannot be implemented as agreed, including identifying the problem, analyzing alternatives, communicating with the customer, updating requirements, and adjusting the system design.

2 hours 30 minutes

M7: Engineering processes Testing (Project 1)

https://academy.nit-institute.com/wp-content/uploads/2024/10/AQPM-M07.png

Will demonstrate traceability and basic practices of system, software, and unit testing on all levels. After this lecture students will be capable to connect all processes on the right side of the V model together with the right side.

In Project 1 participants will try to apply knowledge from ASPICE processes by using major “customer” Change Request. The project will include change requests thru the whole V model including project management.

12 hours

M8: Assessment in practice

https://academy.nit-institute.com/wp-content/uploads/2024/10/AQPM-M08.png

The first lecture of Unit 3 will demonstrate the basics of assessment and prepare students to understand the concept of the ASPICE Process Assessment Model (PAM). The lecture will help students to understand the importance of automotive assessments.

Participants will derive real examples and methods for fulfilling GPs.

2 hours 30 minutes

M9: Assessment preparation and Interview

https://academy.nit-institute.com/wp-content/uploads/2024/10/AQPM-M09.png

The lecture 9 will include important aspects of the interview and how preparation shall be done for any kind of automotive-related assessment. After this lecture students will be capable of participating in ASPICE and safety assessments in the role of the assessed person.

Participants will prepare for the assessment by finding correct BPs and GPs in the given scenarios.

2 hours

M10: Scoring and assessment report (Project 2)

https://academy.nit-institute.com/wp-content/uploads/2024/10/AQPM-M10.png

In this lecture, the key learning will be how scoring and assessment reports are done from the examiner’s side. This will help students to prepare for roles such as Quality Manager, Safety Manager, or Project Manager who is preparing the team for an assessment. Exercise will include some basic patterns of understanding how scores are consolidated.

In Project 2 participants will try to apply knowledge from ASPICE PAM and prepare the assessment report for the arranged scenario.

12 hours

Final exam

none

none

none

1 hour 30 minutes